Machining of Tungsten Carbide

PREMIUM MACHINING is specialized in the machining of cemented

carbides(Tungsten Carbide) tools and custom parts, this super hard material is usually used for

metal molds, cutting machines, industrial machinery, cutting tools,

armor-piercing rounds, other tools and instruments.

Methods of Cemented Carbide Machining:

Because of its extremely high hardness,Tungsten carbide can not be

machined by traditional machining process such as turning, milling or

drilling. Even Tungsten Carbide can be machined by special tools like PCD tools, CNB tools and Ceramic Tools, but these cutting tools lose the sharpness easily. So in PREMIUM MACHINING we tend to grind Tungsten Carbide with diamond tools or machine Tungsten Carbide by electrical discharge machining(EDM), micro-EDM or by ultra precision wire EDM.PREMIUM MACHINING has state of art

machines and technologies specifically adapted to machining of Tungsten carbide.

If you have need to make Tungsten Carbide tools or

parts, please send 3D&2D drawings to quote@premachining.com for evaluation

and quotation. We will get back to you withing 24 hours.

State of the art Seibu Ultra Precsion Wire EDM :

CNC Grinding Shop:

Five-Axis Grinding Shop:

The Cemented carbides(also called Tungsten Carbide)are a range of

composite materials, which consist of hard carbide particles bonded together by

a metallic binder cobalt (Co). Cemented carbides commonly use tungsten carbide

(WC),titanium carbide (TiC), tantalum carbide (TaC) or niobium carbide (NbC) as

the aggregate.Mentions of "carbide" or "tungsten carbide"

in industrial contexts usually refer to these cemented composites. It is mainly

used to make high speed cutting tools,cold working molds, measuring tools and

high wear resistant parts.

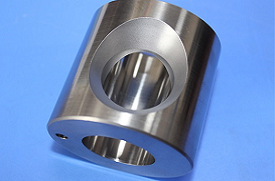

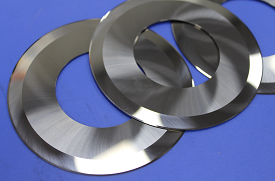

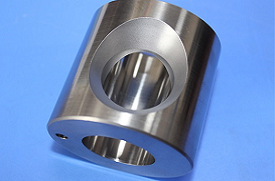

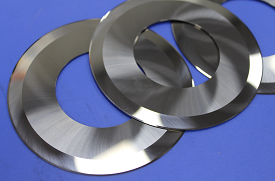

Tungsten Carbide parts:

Advantages of Tungsten Carbide Materials:

(1) High hardness,High wear resistance and High Red Hardness

The hardness of cemented carbide at room temperature can reach 86~93HRA,

equivalent to 69~81HRC.In 900 ~ 1000 ℃ can keep

still keep high hardness, and has excellent wear resistance.Compared with

high-speed tool steel, cutting speed can be 4~7 times higher, life 5~80 times

longer, can cut hard materials which hardness up to 50HRC.

(2) High Strength and Elastic Modulus

The compressive strength of cemented carbide is up to 6000MPa, and its

elastic modulus is (4~7) 105MPa, both higher than that of high-speed steel.But

its bending strength is low, generally 1000~3000MPa.

(3) Good corrosion resistance and oxidation resistance

Generally, it can resist corrosion of atmosphere, acid and alkali, and is

not easy to oxidize.

(4) small linear expansion coefficient

Stable shape and size when working.

Cemented Carbide Grade:

S1、S2、S3、S4、S5、S25、M1、M2、H3、H2、H1、G1 G2 G5 G6 G7

D30 D40 K05 K10 K15 K20 YG3X YG3 YG4C YG6 YG6X YG8 YG9 YG12 YL10.2 YL60 YG15 YG15X YG20 YG25

YG28YT5 YT14 YT15 P10 P20 M10 M15 M20 M30 M40 V10 V20 V30 V40 Z01 Z10 Z20 Z30 YN8 YN6 YN15 CD-630

Applications:

Cemented carbide with high hardness, strength, abrasion resistance and

corrosion resistance, known as the "industry teeth" ,used in the

manufacture of cutting tool, cutting tool, cobalt and wear-resistant parts.

Some key areas where cemented carbide components are used:

1. Military

2. Aviation

3. Machinery

4. Metallurgy

5. Oil Drilling

6. Mining Tools

7. Electronic communications

8. Construction and other fields

This category contains a countless number of applications, but can be

split into three main areas:

• Engineered components

• Wear parts

• Tools and tool blanks