What is CNC Turning?

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret (shown center), with tooling attached is programmed to move to the bar of raw material and remove material to create the programmed result. This is also called “subtraction machining” since it involves material removal. If the center has both tuning and milling capabilities,the rotation can be stopped to allow for milling out of other shapes.

How Do CNC Turning Centers Work?

Exploring the operation of CNC turning centers requires an overview of its essential components, which include:

Chuck: Secures the bar of material for machining.

Spindle: Rotates the chuck across axes for material shaping.

Turret: Moves the material bar in coordination with the computer-aided design (CAD) or computer-aided manufacturing (CAM) blueprint.

Interface: Provides the operator with options for controlling and using turning centers.

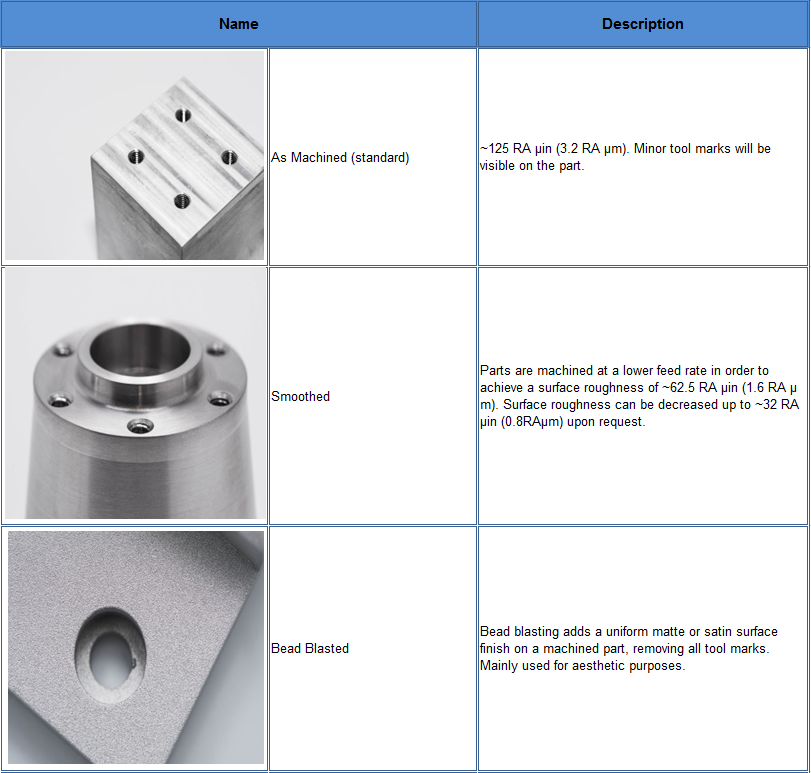

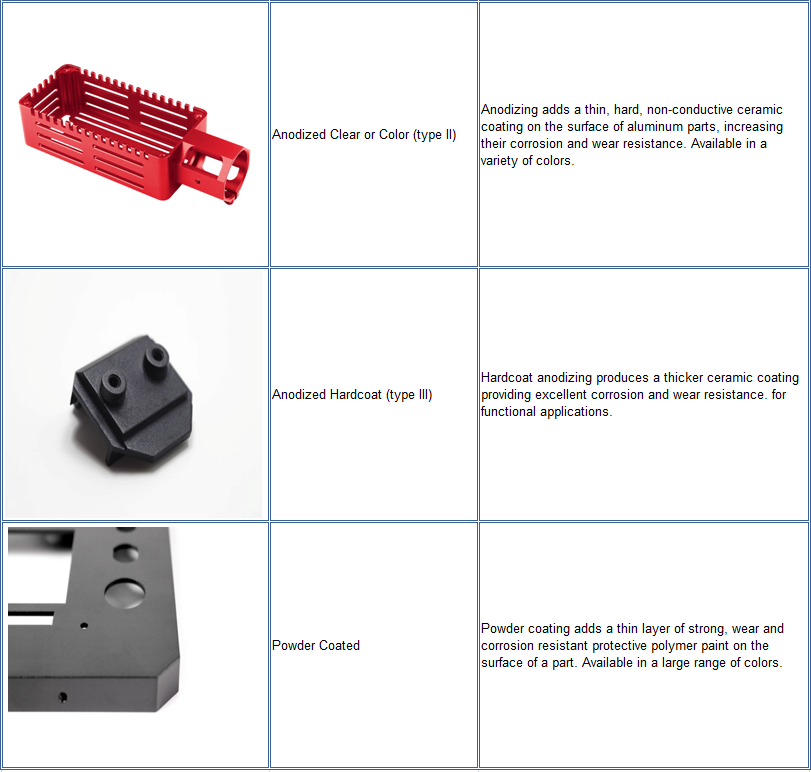

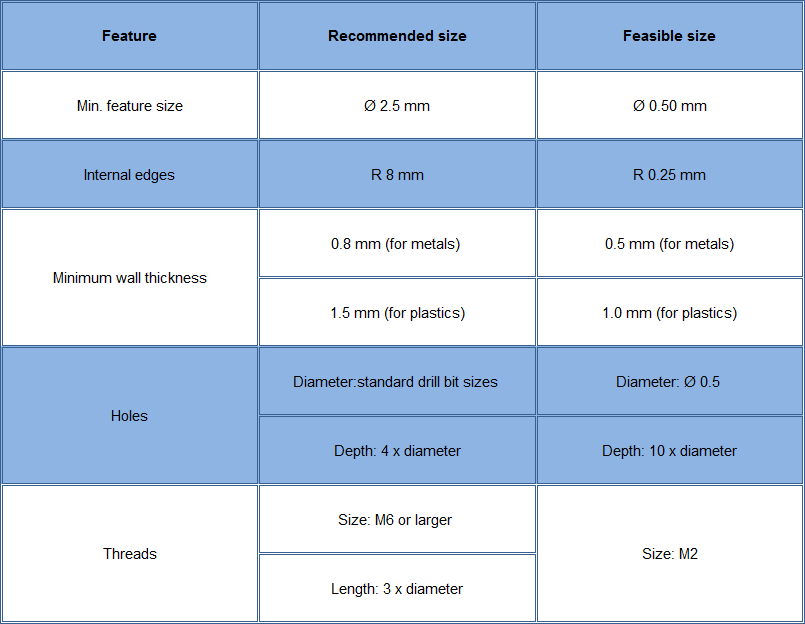

CNC turning design guidelines

The table below summarizes the recommended and technically feasible values for the most common features encountered in CNC machined parts.

Please send us your CAD files at Quote@premachining.com. Indicate the quantity, material, finishing..etc. We will get back to you within 24 hours.

See more about our CNC Turning Serivics.

Contact: Amanda

Phone: +86 138 2885 2656

Tel: +86 138 2885 2656

Add: 2nd Floor NO.39,Zhen'An West Road,Chang An Town, Factory 2:No. 49, 1st Street, Changtang 3rd Industrial Zone, Dalang Town,Dong Guan,China 523878